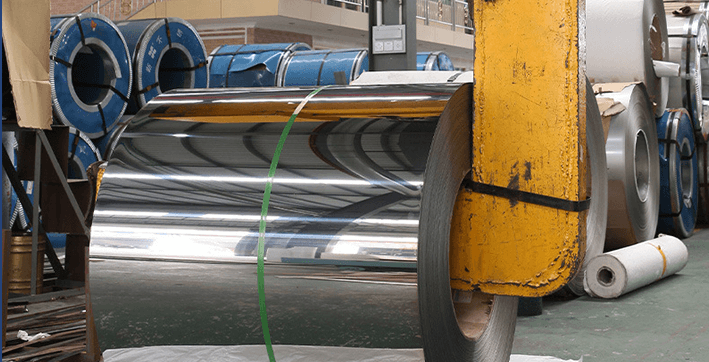

Introduction to stainless steel coil

Stainless steel is a versatile and durable material that has become the go-to choice for industrial applications. It's no wonder why stainless steel coil has gained popularity in various industries due to its numerous benefits. From construction to food processing, stainless steel coil offers a range of advantages that make it an excellent option for various applications. In this blog post, we will explore the advantages of using stainless steel coil in industrial applications and how you can select the right one for your specific needs. So, let's dive into the world of stainless steel coils!

Advantages of using stainless steel coil in industrial applications

Stainless steel coil has become increasingly popular in industrial applications due to its numerous advantages. One of the main benefits is its high resistance to corrosion and rust, making it durable and long-lasting even in harsh environments. This makes stainless steel coil ideal for use in industries such as marine, chemical processing, and oil & gas.

Another advantage is its versatility. Stainless steel can be easily formed into a variety of shapes, sizes and thicknesses, allowing it to be used for a range of applications including tubing, piping, storage tanks and more. It also has excellent heat-resistant properties which make it perfect for use in high-temperature environments.In addition to this, stainless steel is easy to clean which reduces maintenance costs while ensuring hygienic conditions are maintained at all times. It's also environmentally friendly as it's 100% recyclable - contributing towards sustainable development goals.Using stainless steel coils in industrial applications provides a range of benefits that make them an attractive choice over other materials such as carbon or aluminum alloys.

Types of stainless steel coil

Stainless steel coils come in different types, each with its unique features and benefits. The type of stainless steel coil suitable for your industrial application depends on the specific requirements of your project.Austenitic stainless steel is one of the most common types of stainless steel coils used in industrial applications. It contains high levels of chromium and nickel, which makes it highly resistant to corrosion and oxidation. This type of stainless steel is also known for its excellent ductility, making it suitable for forming complex shapes.Ferritic stainless steel coil is another popular option that has a lower level of carbon than austenitic stainless steel. Ferritic stainless steels are magnetic and offer good resistance to stress corrosion cracking, making them ideal for use in harsh environments.Martensitic stainless steels have higher carbon content than other types of steels, giving them greater strength but reduced ductility compared to other grades. They are commonly used in applications where high wear resistance and hardness are required.

Duplex stainless steels combine the best qualities from both ferritic and austenitic grades, offering high strength along with excellent corrosion resistance.In selecting the right type of coil for your project's needs, consider factors such as chemical composition requirements like temperature ranges or pressure specifications alongside budget constraints during procurement decisions.

How to select the right stainless steel coil for your industrial application

When it comes to choosing the right stainless steel coil for your industrial application, there are a few key factors to consider. First and foremost, you need to determine what type of environment your coil will be operating in. Will it be exposed to harsh chemicals or high temperatures? If so, you'll want to look for a grade of stainless steel that can withstand these conditions.Another important consideration is the thickness of the stainless steel coil. Thicker coils may offer more durability and resistance to wear and tear, but they may also be heavier and less flexible than thinner options.It's also worth thinking about the finish of your stainless steel coil. Different finishes can offer different levels of corrosion resistance, as well as aesthetic appeal. Some common finishes include brushed, mirror-polished, and satin.Don't forget about cost when selecting your stainless steel coil. While higher grades or thicker coils may offer better performance in certain situations, they may also come with a higher price tag. Consider your budget carefully before making a final decision.By taking these factors into account when selecting your stainless steel coil, you can ensure that you choose an option that meets all of your needs for performance, durability and cost-effectiveness in any industrial setting.

Conclusion

To sum it up, stainless steel coils are a boon to the industrial sector. They offer a unique combination of strength, durability, and corrosion resistance that is suitable for various applications. From food processing to oil refineries, these coils are widely used in different industries across the globe.Selecting the right type of stainless steel coil plays an essential role in ensuring optimal performance and longevity of equipment. It is crucial to consider factors like grade, thickness, width, finish, and application requirements before choosing a particular coil.Investing in high-quality stainless steel coils can provide significant benefits for your business. They not only help you save money by reducing maintenance costs but also ensure safe working environments for employees while improving overall productivity. So why wait? Start exploring your options today!Please contact us if you need.zoey@hjmlsteel.com

Recommended News

Recommended News

Wechat

Wechat Whatsapp

Whatsapp