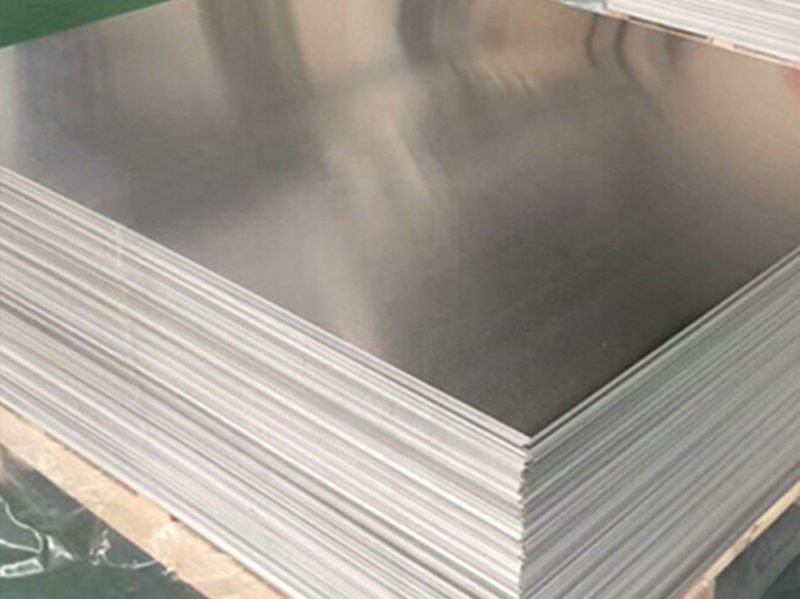

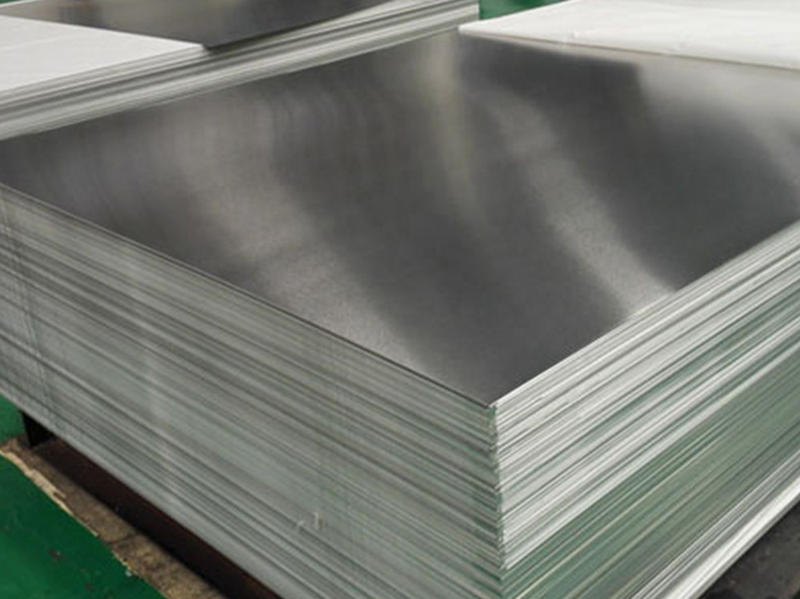

1050 aluminum sheet and strip is a product in the pure aluminum sheet series. Since it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in conventional industries. It has the characteristics of high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, and can accept contact welding and gas welding.

Description

DescriptionProduct Introduction

According to your request,each size can be selected for different application.Please contact us! | |

Product name | 1050 Aluminum Sheet/Plate |

Thickness | 0.1mm-500mm |

Width | 100mm-2650mm |

Length | As customer's requirements |

Temper | O, H12, H14, H16 H18, H19, H22, H24 H26, H28, H112, etc. |

Features | 1) High plasticity 2) Strong corrosion resistance 3) High conductivity 4) High thermal conductivity |

Application | 1) Billboard 2) Building exterior decoration 3) Bus body 4) High-rise and factory wall decoration 5) Kitchen sink 6) Lamp holder 7) Fan blades |

Surface | Flat every pieces covered with PE film |

Packing | Export standard wooden pallets (as per requirements) |

Remark | Specific requirement of alloy grade,temper or specification can be discussed at your request |

Product Performance

chemical composition

Magnesium Mg: 0.05; Zinc Zn: 0.05; Manganese Mn: 0.05; Titanium Ti: 0.03; Vanadium V: 0.05; Iron Fe: 0.40; Individual: 0.03.

mechanical properties

Tensile strength σb (MPa): 60~100; Elongation δ/(%): ≥23; Elongation 50mm/(%): ≥25

Note: Longitudinal mechanical properties of pipe at room temperature

Specimen Size: All Wall Thicknesses

Heat treatment specifications:

1) Complete annealing: heating at 390-430°C; depending on the effective thickness of the material, the holding time is 30-120min; cooling with the furnace to 300°C at a speed of 30-50°C/h, and then air-cooling.

2) Rapid annealing: heating at 350-370°C; depending on the effective thickness of the material, the holding time is 30-120min; air or water cooling.

3) Quenching and aging: quenching at 500-510°C, air cooling; artificial aging at 95-105°C, 3h, air-cooling; natural aging at room temperature for 120h.

1050 Aluminum Sheet Supplier - HJMLSTEEL

HJMLSTEEL specializes in OEM&ODM services of various stainless steel, aluminum, galvanized steel sheets, coils, pipes, bars, pipe fittings, high nickel alloy steel products, high temperature resistant products, etc.

Related Products

Durable

Durable High Quality

High Quality

Material Selection Anti Corrosion And

Anti Corrosion And

wear resistance Factory

Factory

Outletauthentic Authentic Date

Authentic Date Support

Support

Customzation

Detail Determines Quality

01Rugged And Practical

01Rugged And PracticalAutomatic cutting machine cutting,no burr on the edge corrosion resistance,good mechanical properties,oxidation resistance and not easy to rust

02Craftsman-Ship

02Craftsman-ShipAutomatic cutting machine cutting,no burr on the edge corrosion resistance,good mechanical properties,oxidation resistance and not easy to rust

03Arbitrary Cutting

03Arbitrary CuttingAutomatic cutting machine cutting,no burr on the edge corrosion resistance,good mechanical properties,oxidation resistance and not easy to rust

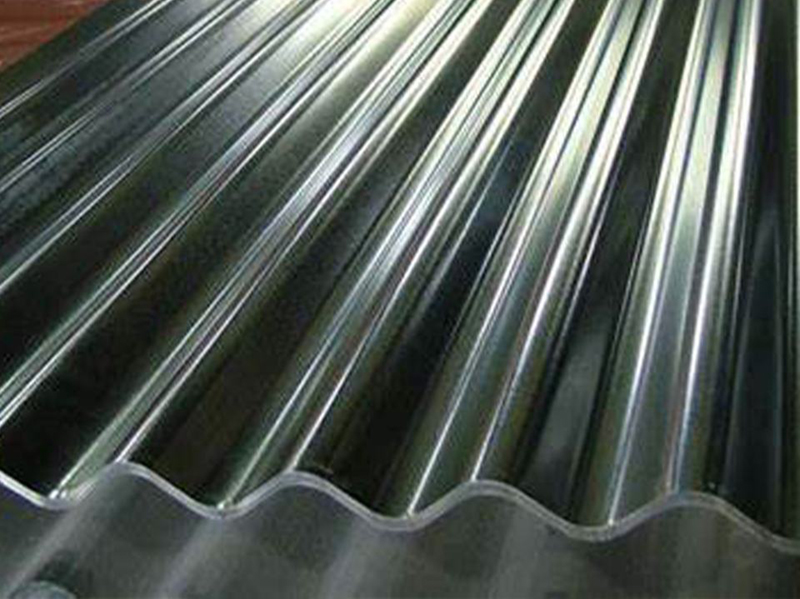

Product Display

jenny@hgmlsteel.com

jenny@hgmlsteel.com Recommend Products

Recommend Products

Wechat

Wechat Whatsapp

Whatsapp