Are you looking for a versatile and durable material for your next project? Look no further than 1050 aluminum sheet! This high-quality metal boasts numerous characteristics that make it a go-to choice for various applications. From its impressive chemical composition to its physical properties, there's no doubt that this aluminum sheet is worth considering. In this blog post, we'll dive into the uses and benefits of 1050 aluminum sheet, so let's get started!

Chemical composition of 1050 aluminum sheet

1050 aluminum sheet is a pure aluminum product that contains 99.5% of aluminum with some impurities. The chemical composition of this alloy makes it highly resistant to corrosion, which is why it is widely used in various industries.In addition to the high purity level, other elements present in the chemical composition of 1050 aluminum sheets include silicon (Si), iron (Fe), copper (Cu) and zinc (Zn). These elements are present in trace amounts and do not affect the properties of the metal significantly.The presence of magnesium and manganese in significant quantities can lead to increased strength, but these elements are usually absent from 1050 aluminum sheets because they are considered impurities.The absence or low levels of other metals allows for excellent electrical conductivity as well as being lightweight and easy to work with. This makes them an ideal choice for applications like cooking utensils, reflectors, signs, nameplates among others.The chemical composition of 1050 Aluminum Sheet offers many advantages over other alloys making it one of the most popular options available today.

Physical properties of 1050 aluminum sheet

1050 aluminum sheet is a popular choice for a variety of applications, thanks in part to its impressive physical properties. One of the key characteristics of 1050 aluminum sheet is its excellent corrosion resistance, making it ideal for use in marine environments or other situations where exposure to moisture is likely.In addition to being highly resistant to corrosion, 1050 aluminum sheet also boasts superior thermal conductivity and electrical conductivity. This makes it an excellent option for manufacturing products such as heat sinks or electronic components that require efficient heat transfer.Another important physical property of 1050 aluminum sheet is its high reflectivity. With a surface reflectance greater than 80%, this material is often used in lighting fixtures and reflective mirrors.Despite these impressive properties, 1050 aluminum sheet remains lightweight and easy to work with. It can be easily formed into a wide range of shapes and sizes using standard metalworking techniques like cutting, bending, and welding.The unique combination of physical properties offered by 1050 aluminum sheet make it an incredibly versatile material suitable for many different uses across various industries.

Temper types of 1050 aluminum sheet

1050 aluminum sheet is available in various temper types to suit different applications. The temper type determines the hardness, strength and formability of the material.The most common temper for 1050 aluminum sheet is H14, which means it has been strain hardened and partially annealed. This makes it a good choice for welding, brazing and soldering as well as general fabrication.Another popular temper type is O or soft annealed, which means the material has been fully annealed to improve its ductility and formability. This makes it ideal for deep drawing applications where complex shapes are required.For applications where greater strength is needed, 1050 aluminum sheet can be supplied in H18 or full-hard temper. This provides maximum hardness and tensile strength but reduced ductility.Other available tempers include H12 (quarter-hard), H16 (three-quarters hard) and H22 (1/4 hard). Each of these tempers offers a balance between strength, ductility and formability depending on the specific application requirements.Choosing the right temper type is crucial to achieve optimal performance from 1050 aluminum sheet in any given application.

Application of 1050 aluminum sheet

The 1050 aluminum sheet is a versatile material that can be used across various industries. Its unique properties make it suitable for numerous applications, especially in the construction and manufacturing sectors.One of the most common uses of 1050 aluminum sheet is in roofing and cladding systems. Due to its high corrosion resistance, this type of aluminum sheet is an excellent choice for buildings located near coastal areas or those exposed to harsh weather conditions.In addition, the 1050 aluminum sheet is extensively used in the packaging industry. It's lightweight and malleable nature makes it perfect for creating containers such as cans and foil wraps.Moreover, this versatile material is also highly sought after for electrical purposes like transformer winding due to its excellent conductivity properties. The 1050 aluminum sheet has low toxicity levels making it ideal for use in food processing equipment such as cooking utensils and appliances.With advancements in technology, there has been increasing demand for 1050 aluminum sheets' application within aerospace engineering projects due to their lightweight structure which reduces fuel consumption significantly.The different characteristics possessed by the 1050 aluminium sheets make them one of the most widely used materials across multiple industries worldwide.

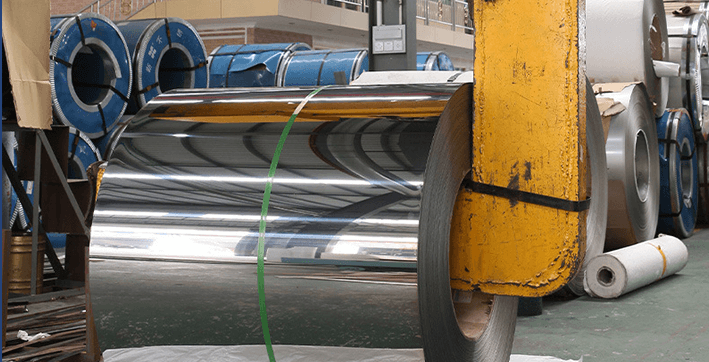

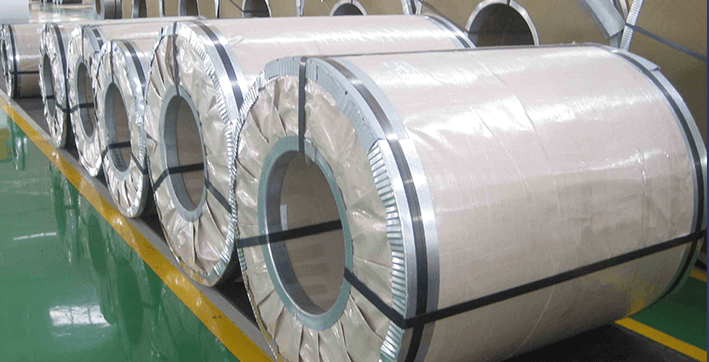

Packaging and transportation of 1050 aluminum sheet

Packaging and transportation of 1050 aluminum sheet is crucial to maintain the quality of the product. The sheets are carefully packed in wooden pallets or cases, covered with plastic films to prevent any scratches or damage during transit.The packaging process includes marking each sheet with unique identification numbers for easy tracking. This helps in identifying any issues that may arise during transportation and allows for quick resolution.Transportation of 1050 aluminum sheet can be done through various means such as trucks, trains, or ships depending on distance and location. The mode of transport must ensure safe handling and timely delivery while maintaining the integrity of the product.During transit, proper care should be taken to avoid exposure to harmful elements like moisture or extreme temperatures that could cause corrosion. For this reason, it's important to choose a reliable logistics company with experience in handling sensitive materials like aluminum sheets.In summary, packaging and transportation play a significant role in ensuring that 1050 aluminum sheet reaches its destination safely without any damage. Proper packaging ensures that products remain intact throughout their journey while careful handling ensures they arrive at their destination ready for use without compromise on quality.

Conclusion

In conclusion, 1050 aluminum sheet is a versatile and widely used material due to its excellent characteristics. With high corrosion resistance, formability, conductivity and weldability, the sheet can be easily formed into different shapes for various applications.The temper types of 1050 aluminum sheet also provide options for users depending on their specific needs. The softest H1X temper type is ideal for deep drawing while the hardest H3X temper type works well in structural applications.Whether it's in manufacturing or construction industries, 1050 aluminum sheets are always reliable as they meet industry standards with consistent quality. And with proper packaging and transportation procedures followed during shipping to avoid damage from moisture or other factors that may affect its properties; this material will continue being an essential part of many products around the world.

Recommended News

Recommended News

Wechat

Wechat Whatsapp

Whatsapp