Introduction to 1050 aluminum sheet

Are you familiar with 1050 aluminum sheet? If not, then it's time to get acquainted with this versatile material. As one of the most commonly used aluminum alloys, 1050 aluminum sheet has a wide range of applications in various industries. In this blog post, we'll take a closer look at what makes 1050 aluminum sheet so popular and why it might be the right choice for your next project. From its advantages and processing technology to market outlook and more, let's dive into everything you need to know about 1050 aluminum sheet!

The advantages of 1050 aluminum sheet

1050 aluminum sheet is a popular choice among various industries due to its numerous advantages. Firstly, it has excellent corrosion resistance which makes it ideal for use in marine environments or other outdoor applications. It also has good electrical conductivity and thermal properties, making it suitable for electronic devices and heat transfer equipment.Another advantage of 1050 aluminum sheet is its high formability. This means that it can be easily shaped into different forms without cracking or breaking, making it perfect for the manufacturing of intricate parts such as tubes, pipes, and profiles.In addition to this, 1050 aluminum sheet is lightweight yet strong, providing a cost-effective solution for projects that require both strength and weight savings. Its non-toxic nature also makes it ideal for food packaging applications where safety is crucial.Furthermore, 1050 Aluminum Sheet offers excellent workability characteristics including deep drawing capabilities which are useful in forming complex shapes with smooth surfaces at high production rates while reducing costs associated with fabrication processes such as welding or brazing.The benefits of using 1050 aluminum sheet make it an attractive option across many industries including automotive manufacturing; aerospace engineering; construction materials like roofing panels & siding; consumer products like cookware sets & kitchen appliances!

The applications of 1050 aluminum sheet

1050 aluminum sheet is widely used in various industries due to its excellent properties. One of the most significant applications of 1050 aluminum sheet is in electrical appliances and electronics, such as televisions, computers, and mobile phones.The high conductivity of 1050 aluminum makes it an ideal material for electronic components that require heat dissipation. Additionally, the corrosion resistance property also ensures these products will last long without rusting or deteriorating over time.Another application for 1050 aluminum sheet is in packaging materials. The light-weight nature of this metal makes it perfect for food packaging since it does not add any extra weight to the container. Moreover, its non-toxicity property assures that food remains fresh and healthy when packed with this material.Due to their high reflectivity rate, 1050 aluminum sheets are also commonly used in lighting fixtures such as lamps and reflectors. This reflects light efficiently while still allowing a uniform distribution of luminosity throughout space.Some other common applications include road signs and traffic lights because they have low density but exceptional durability which withstands harsh conditions caused by weather or heavy winds.

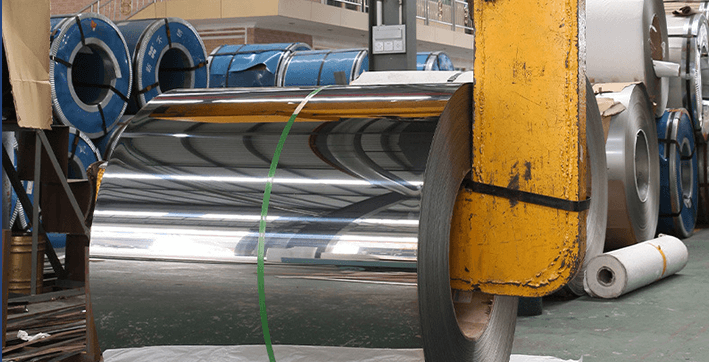

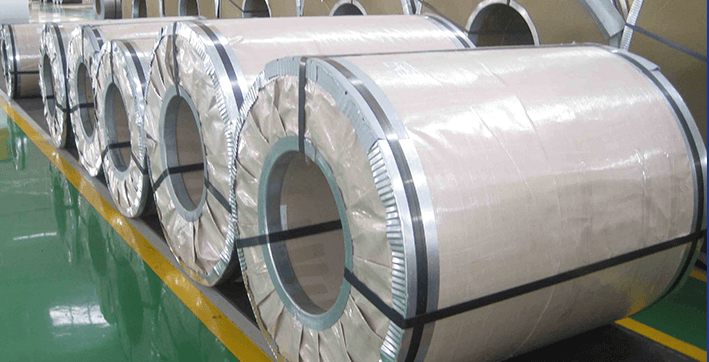

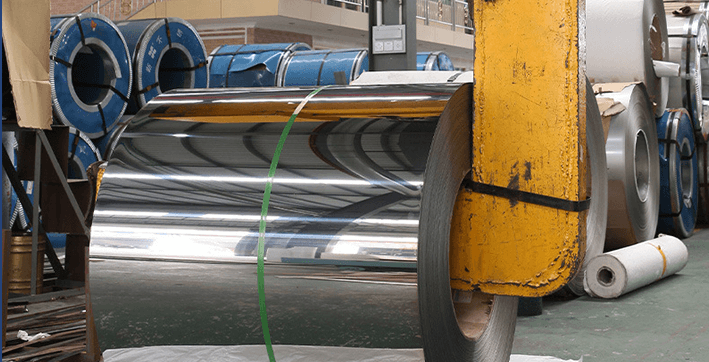

The processing technology of 1050 aluminum sheet

When it comes to processing 1050 aluminum sheet, there are several methods that can be used. One of the most common methods is cold working, which involves deforming the material at room temperature. This process helps to improve the mechanical properties of the sheet while retaining its ductility.Another popular method is hot working, which involves heating the material above its recrystallization temperature before shaping it into various forms such as plates or strips. This technique can help produce sheets with better surface finishes and improved formability.To enhance the strength and hardness of 1050 aluminum sheet, heat treatment processes like annealing or quenching may also be employed. Annealing can refine grain structures and reduce internal stresses in a sheet while quenching hardens it by rapidly cooling it after heating.Surface treatments like anodizing or painting may also be applied to 1050 aluminum sheets to improve their corrosion resistance and aesthetics respectively.Understanding these various processing techniques will enable manufacturers to produce high-quality 1050 aluminum sheet products suitable for a wide range of applications.

The market outlook for 1050 aluminum sheet

As we have seen, 1050 aluminum sheet offers a range of benefits for various applications due to its high conductivity, corrosion resistance, and workability. The processing technology for this material is also well-established, making it an attractive option for manufacturers.Looking ahead, the market outlook for 1050 aluminum sheet is positive. With increasing demand in industries such as electronics and automotive manufacturing, the use of this material is expected to rise. Additionally, advancements in processing technology are likely to improve the efficiency and cost-effectiveness of producing 1050 aluminum sheet.If you're looking for a versatile and reliable material for your next project or application, consider using 1050 aluminum sheet. Its unique properties make it an excellent choice with many potential benefits now and in the future.If you want to know more about this product, please contact zoey@hjmlsteel.com

Recommended News

Recommended News

Wechat

Wechat Whatsapp

Whatsapp